Welcome to the website. +86-13953285555

Raymond mill is a commonly used crushing equipment, mainly used to grind raw materials into fine powder. Here's how it works:

1. Raw material feeding: Raw materials enter the grinding chamber of the Raymond mill through the feeding device.

2. The functions of grinding rollers and grinding rings: The core components of Raymond mill are composed of a pair of rotating grinding rollers and a fixed grinding ring. The raw material is sandwiched between the grinding roller and the grinding ring. The rotation of the grinding roller causes the material to be squeezed, rubbed and sheared.

3. Grinding and classification: During the grinding process, the raw materials are gradually ground into fine particles. The function of the grinding ring is to re-grind larger particles to ensure the uniformity and fineness of the powder. At the same time, a grading device is installed in the grinding chamber, which can classify the powder as needed and control the particle size of the powder.

4. Powder discharge: After grinding and classifying, the fine powder is blown or transported to the powder collection device by wind or mechanical force to complete the entire grinding process.

Production Line of desulfurized powder:

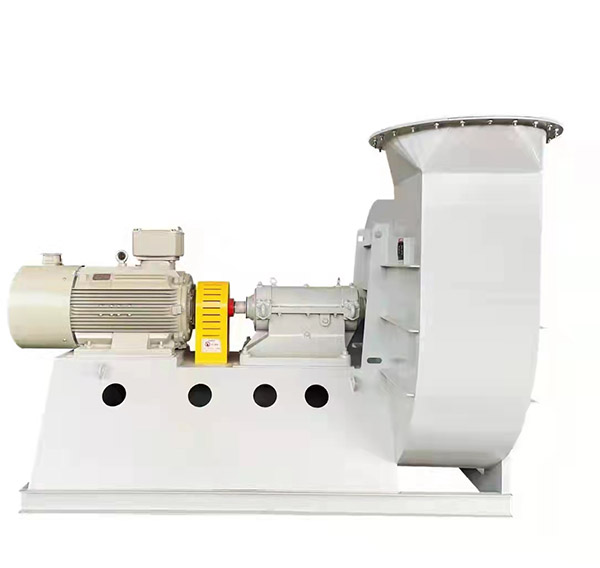

Raymond mill uses a lot of equipment in operation, such as blowers:

Different types of Raymond mills have differences in grinding raw materials into fine powder and internal structures, but their basic working principles are similar.